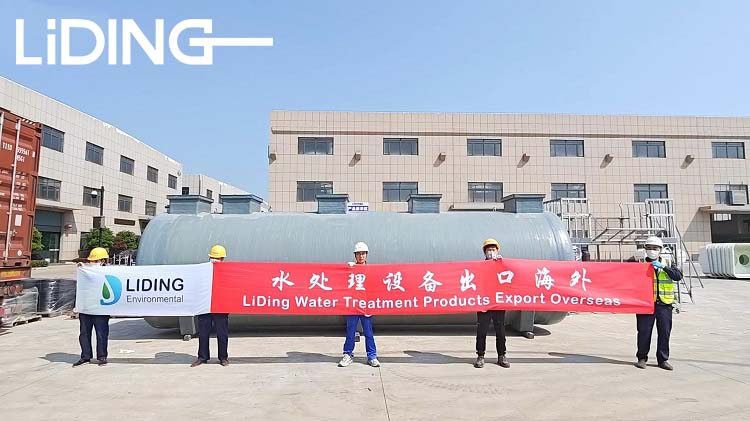

In a recent logistics milestone, Liding successfully dispatched a batch of integrated johkasou sewage treatment plants from its intelligent manufacturing base. The equipment is destined for deployment in a remote desert camp, where environmental resilience and operational efficiency are key to successful wastewater management.

Prior to shipment, factory personnel followed strict packaging and quality assurance protocols. Each component was carefully wrapped, reinforced, and loaded to ensure maximum protection during long-distance transportation under extreme climate variations. The dedication and attention to detail from Liding’s teams reflect the company’s commitment to excellence from factory to field.

Specially designed for harsh and decentralized environments, the shipped sewage treatment systems feature Liding’s modular johkasou built with corrosion-resistant FRP materials. The units incorporate MBBR core processes, enabling reliable treatment performance with a compact footprint. Their key advantages include:

• Underground design, small footprint, covered with soil for greening

• Stable effluent quality, meeting international discharge standards even under fluctuating loads

• In environments where infrastructure is limited and climate conditions are extreme, Liding’s integrated sewage solutions provide a dependable answer to sanitation needs—ensuring safety, sustainability, and ease of maintenance.

• Intelligent Control: Intelligent monitoring technology can be used to achieve fully automatic operation, stable operation, intuitive and easy to operate.

This shipment marks another successful step in Liding’s global journey to deliver intelligent, site-adaptable wastewater treatment solutions across complex terrains and challenging locations.

Post time: May-07-2025